-

Products

GYS WELDING

AND CUTTING

EQUIPMENT Discover our range - Home

- About

- Training

- Online Store

- Contact

IRT UV SPOTCURE

CODE: 750746

BRAND: IRT

IRT UV SPOTCURE

The safest and best curing performance for minor to moderate repairs, that will benefit all body shops - reduce curing time from minutes to seconds. Active safety systems in vehicles are increasingly pre-venting and reducing damage. In the future, this trend will continue and will increase the pressure on body shops to work more efficiently and profitably. With UV Spot-Cure, curing will reduce from minutes to seconds.

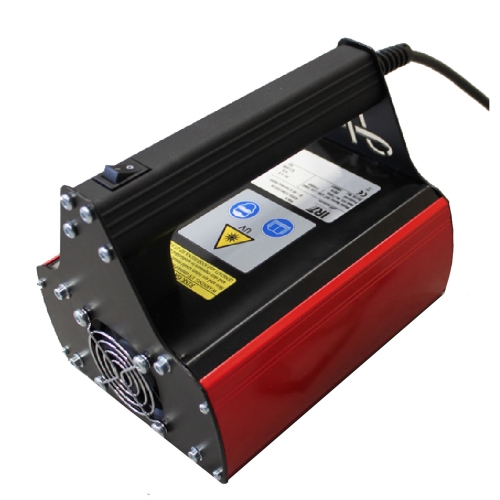

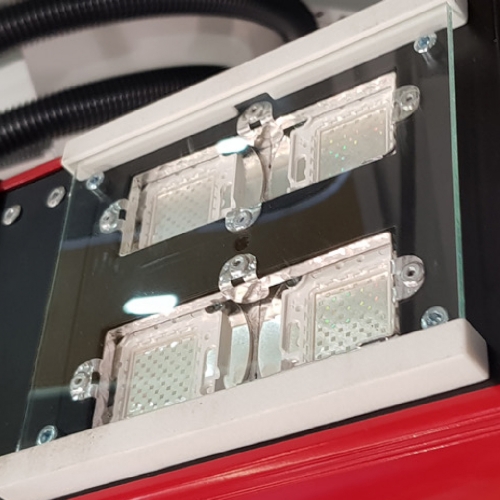

UV SpotCure is a robust, easy-to-use, handheld UV-LED dryer designed for professional use. The UV SpotCure is equipped with four 100W LED modules emitting UV and visible light, clearly making this unit the most powerful portable UV-curing solution on the market. UV SpotCure is designed to live up to regulatory compliance and international safety standards.

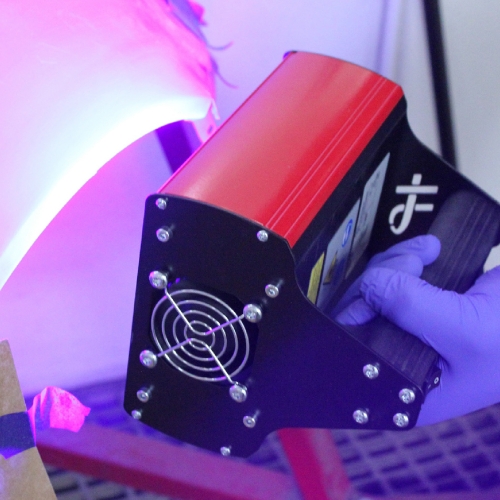

The UV SpotCure generates more UV-A intensity in a shorter time and more precisely, enabling the user in moving the unit in the same way as when painting with a spray gun, with no risk of damaging the surface. This unit covers a curing area typically 10 times larger than the competition.

UV SpotCure will easily cover even a larger area, but still at the same high-quality curing capacity as with static placement.

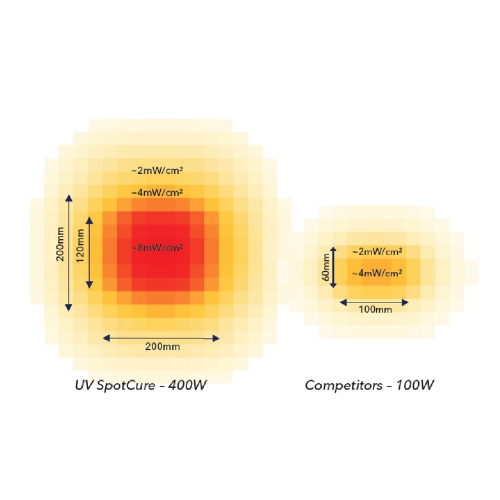

HEDSON VS COMPETITORS

Measured at 100mm between LED and substrate, Hedson UV SpotCure achieves a light intensity on the surface of 8 mW/cm². Competitors achieve an intensity of 4 mW/cm², or lower. The less power or light intensity that arrives on the surface, the higher the risk that UV-A radiation will not penetrate the layer 100%.

UV-LED TECHNOLOGY

UV curing technology with light-emitting diodes (LEDs), is significantly more environmentally friendly for the technician as the working zone is ozone-free and as the LED lamps generate low, near-instant, curing intensity, cold curing the painted surface without heating up the surrounding air. Overall maintenance is reduced and the elimination of a warm-up cycle reduces technician downtime. Lastly, the LED lamps work at lower temperatures than standard UV bulbs, providing an added margin of safety for your shop.

BENEFITS

The UV SpotCure quickly provides superior intensity, correct wavelength, and proper curing performance through the whole thickness of the paint, ensures UV-paint materials to be 100% cured, and enables reliable paint processes in body shops. Low energy consumption and a long LED lifetime keep the cost per curing job very low.

Different to, as nowadays commonly used light-emitting LEDs, UV-A LED’s turn a considerable part of the needed electrical energy into heat within the LED structure. With built-in fans, the UV-A LED’s and internal components are kept cool, reducing the risk of overheating the units, also extending the lifetime of the lamps to beyond 20,000 hours, with a minimal loss of curing power over that time.

- Fast curing time

- Easy to use

- Low-temperature processing

- Minimal maintenance

- Safe to use in your bodyshop

- Voltage: 220-240V, 1Ph/PE

- Rec. Fuse: 10A

- Frequency: 50-60 Hz

- Power: 0.4kW

- Current: 1.7A

- Noise Level: < 70dB (A)

- Cord length: 10 m

- Weight: handheld unit 1,56 kg or 7,1 kg total (incl. rack)

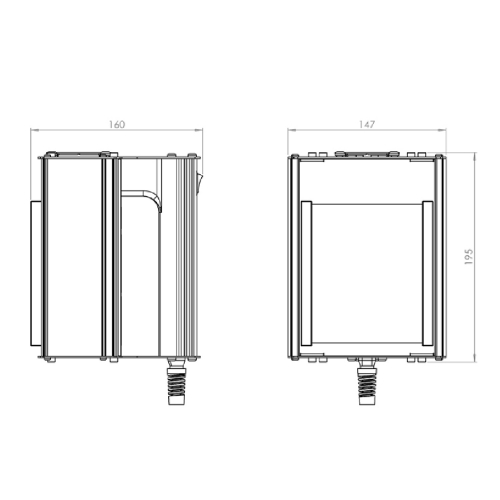

- Measurements handheld unit: Width 147 mm x Height 195 mm x Depth 160 mm

- Measurements unit rack: Width 245 mm x Height 370 mm x Depth 270 mm

- UV Gun

- UV safety glasses,

- 1 x cable hook